In the dynamic and rapidly evolving field of diagnostics, the need for precise, efficient, and scalable production methods is essential. Certainly! Here's a clearer version of the sentence:

"Bioreactors have become essential tools for optimizing and conducting research in diagnostic production. They provide controlled environments for growing cells and microorganisms that are crucial for making diagnostic reagents and other products."

This article explores the role of bioreactors in improving the efficiency, consistency, and scalability of diagnostic production and provides insights into their application for industry experts.

The role of bioreactors in diagnostic production

Bioreactors are engineered systems that provide a controlled environment for biological reactions and processes. In the context of diagnostic production, bioreactors are used to cultivate cells, bacteria, and other microorganisms that produce essential components such as antigens, antibodies, enzymes, and other biological materials needed for diagnostics.

Optimization of production conditions

- Parameter control: Bioreactors allow for precise control of critical parameters such as pH, temperature, dissolved oxygen, and nutrient supply. This control is vital to optimize the yield and quality of diagnostic components, as even slight variations in these parameters can significantly affect biological activity and product purity.

- Scalability: Bioreactors facilitate the upscaling of production processes from the laboratory to industrial scale. By optimizing conditions in small-scale bioreactors, researchers can develop protocols that are directly transferable to larger systems, ensuring consistency in production across different scales.

Research and Development

- Experimental flexibility: Bioreactors provide a versatile platform for conducting research on different cell lines and microbial strains. This flexibility is crucial for developing new diagnostic products, as it allows for exploration of various production methods, medium formulations, and process conditions.

- High-throughput screening: Advanced bioreactor systems equipped with automation and parallel processing capabilities enable high-throughput screening of different experimental conditions. This accelerates the research process by allowing multiple experiments to be conducted simultaneously, leading to faster identification of optimal conditions.

Quality control and consistency

- Batch consistency: Bioreactors ensure uniformity between production batches, which is essential for the reliability of diagnostic products. By maintaining consistent production conditions, bioreactors reduce variability between batches, improving the reproducibility of diagnostic assays.

- In-Process monitoring: Modern bioreactor systems are equipped with sophisticated sensors and monitoring tools that provide real-time data on key process parameters. This capability allows for immediate process adjustments, ensuring that the final product meets strict quality standards.

Production of Diagnostic Components

- Antibody production: Bioreactors are widely used in the production of monoclonal and polyclonal antibodies, critical components in many diagnostic tests. The ability to cultivate hybridoma cells or other antibody-producing cells in a controlled environment ensures high yields and functional integrity of the antibodies.

- Enzyme production: Enzymes used in diagnostic assays, such as polymerases and reverse transcriptases, can be efficiently produced in bioreactors. The controlled environment minimizes the risk of contamination and degradation, ensuring that the enzymes retain their activity and stability

Case Study: Optimization of Antibody Production Using Bioreactors

In a recent study, a team of researchers used a bioreactor system to optimize the production of monoclonal antibodies for use in diagnostic assays. By systematically varying culture conditions, including nutrient composition, oxygen levels, and agitation rates, the researchers were able to significantly increase antibody yield while maintaining high specificity and affinity. The optimized process was successfully scaled from a laboratory bioreactor to an industrial-scale system, demonstrating the scalability and effectiveness of bioreactor-based optimization in diagnostic production.

The key factor in achieving high-quality products

The integration of bioreactors in the optimization and research phases of diagnostic production is a key factor in achieving high-quality, scalable, and consistent products. With the growing demand for advanced diagnostics, the role of bioreactors in streamlining production processes will become increasingly important. For industry experts, leveraging the capabilities of bioreactors offers a pathway to innovation and excellence in diagnostic production, ensuring that final products meet the highest standards of performance and reliability.

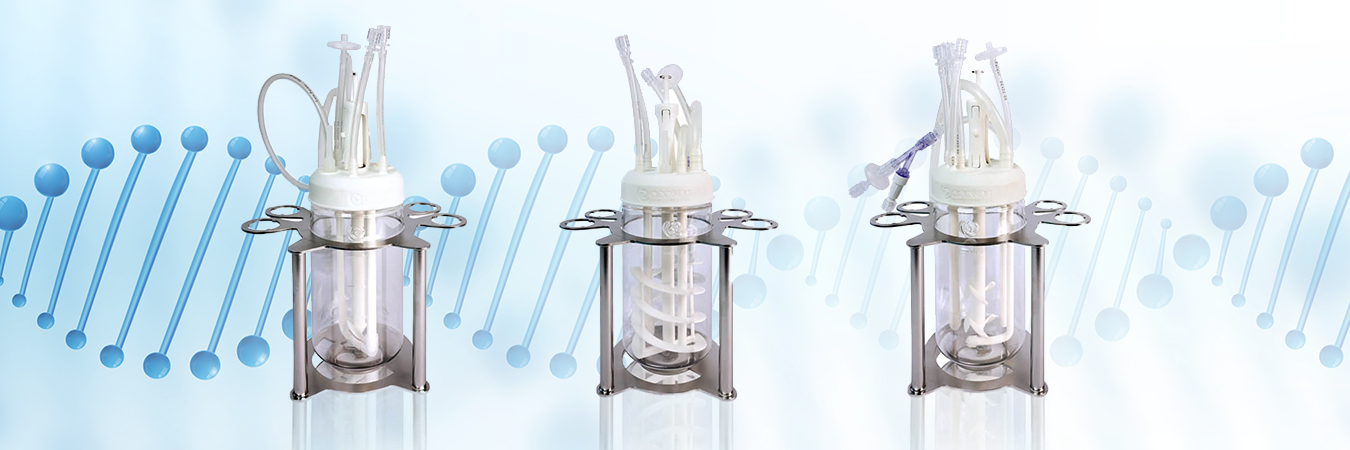

Steroglass, the official Italian distributor of Getinge bioreactors for the Italian market, is able to offer customers the widest range of solutions tailored to specific research and process needs.